Colored craft paper, with its vibrant hues and diverse textures, has found widespread use in arts and crafts, decorative design, and packaging. However, its limited water resistance poses a challenge to its long-term usability and effectiveness in certain applications. This article delves into the water resistance of colored craft paper, exploring the factors that influence it and examining methods to improve its water-repellent properties.

Water resistance refers to a material's ability to maintain its physical and chemical integrity when exposed to moisture. For colored craft paper, good water resistance means that the paper retains its strength, shape, and color when subjected to humid environments or accidental contact with water. It should not exhibit noticeable fading, warping, or tearing.

Different types of pulp have varying impacts on water resistance. Generally, wood pulp-based papers exhibit better water resistance compared to grass pulp papers. This is attributed to the longer and more robust wood fibers, which provide enhanced structural stability.

The choice of dyes or pigments used for coloration also affects water resistance. Water-soluble dyes tend to dissolve and diffuse when in contact with water, while insoluble pigments offer better color stability.

Sizing is a crucial process in enhancing paper's water resistance. Sizing agents, such as starch, polyvinyl alcohol, and synthetic resins, form a protective layer on the paper's surface, preventing moisture penetration.

Applying a waterproof coating, such as polyurethane or acrylic resin, to the paper's surface significantly improves its water resistance. These coatings not only repel water but also enhance the paper's gloss and abrasion resistance.

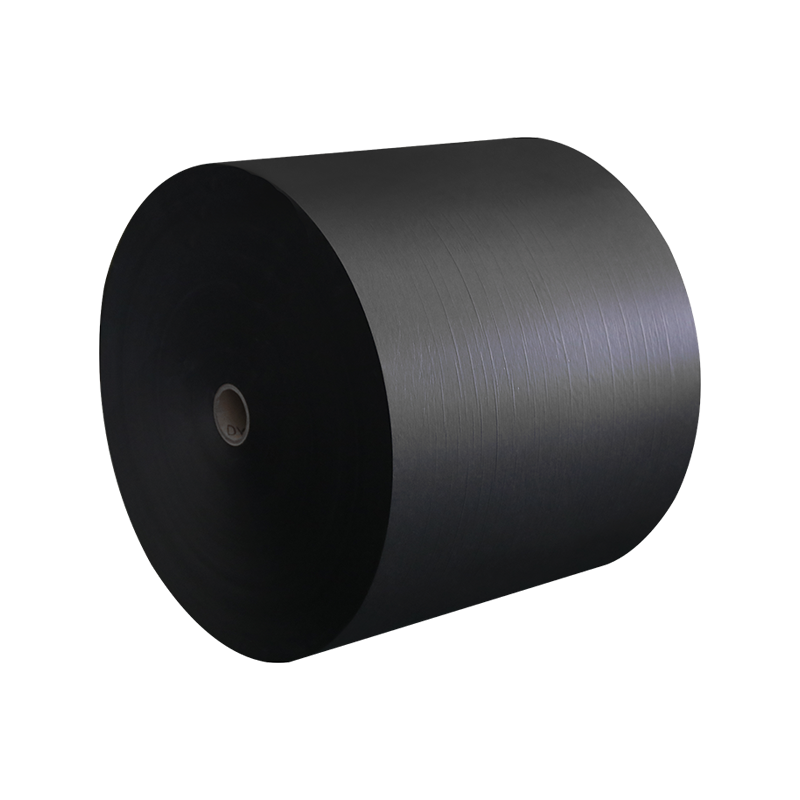

Opt for wood pulp papers with dense fiber structures and high strength as the base material. Utilize insoluble pigments for coloring.

Introduce sizing agents into the paper pulp, ensuring their uniform distribution during paper formation. This significantly enhances the overall water resistance of the paper.

Apply a layer of sizing agent on the paper's surface to further reinforce its water-repellent properties. Employing high-efficiency sizing agents like crosslinked polyvinyl alcohol yields better results.

Polyurethane coatings provide excellent water resistance and flexibility, offering effective waterproof protection without compromising the paper's hand feel.

Acrylic coatings not only impart water resistance but also exhibit good light and weather resistance, making them suitable for colored craft paper used in outdoor environments.

Water resistance is a critical factor determining the longevity and aesthetic appeal of colored craft paper. By employing high-quality raw materials, optimizing sizing processes, and utilizing waterproof coatings, the water resistance of colored craft paper can be significantly enhanced. As new materials and technologies emerge, the future holds promise for further advancements in colored craft paper's water resistance, catering to an even broader range of applications.