In modern society, the packaging industry has become an indispensable part of daily life. Whether it is food, cosmetics, electronic products, or other consumer products, packaging is needed to protect products, enhance brand image, and provide consumers with a convenient use experience. As one of the core components of packaging materials, packaging base paper plays a vital role.

Packaging base paper is mainly made of natural raw materials such as wood pulp and plant fiber through special processes. Its production process includes pulping, papermaking, drying, calendering and other steps, which directly affect the quality and performance of packaging base paper.

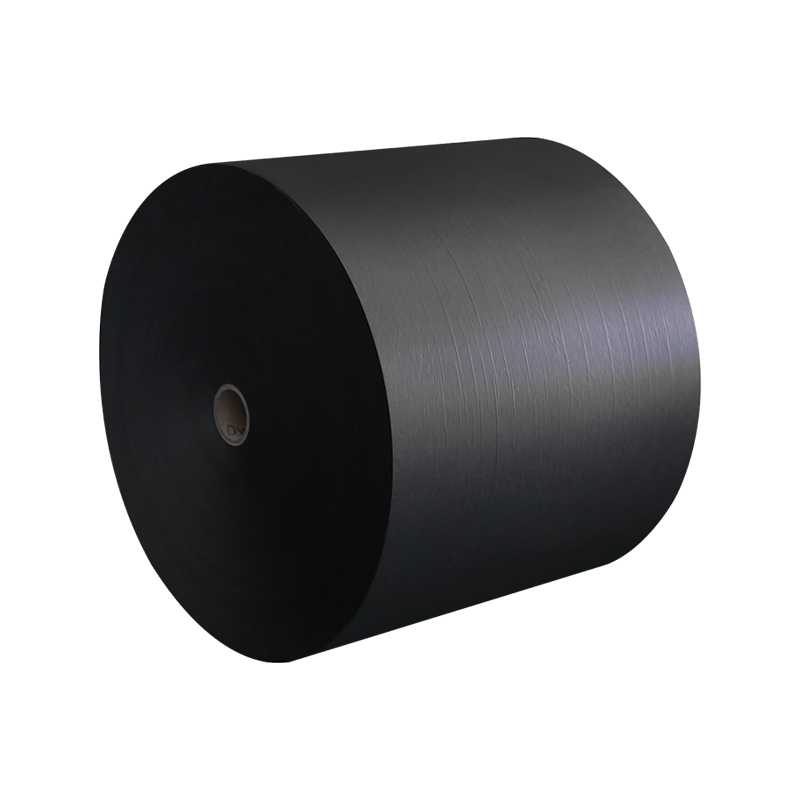

There are many different types of packaging base paper, which are mainly classified according to their use, quality requirements and different characteristics of paper. The following are several common types of packaging base paper:

Kraft paper is a thick and durable packaging paper, which is usually used to make packaging products such as paper bags, cartons and paper bags. It has strong tensile and tear resistance and is often used to package heavier or more solid items.

Coated paper is a coating layer applied to the surface of the base paper to make its surface smoother, and is usually used for high-quality printing and packaging. This kind of paper is often used for cosmetic packaging, food packaging and high-end commodity packaging.

Corrugated paperboard consists of two layers of flat paper and a layer of corrugated paper in the middle, and is widely used in the manufacture of cartons and packaging boxes. It has good compression resistance and cushioning properties, and is suitable for use when transporting and storing items.

Grey board is a thick and hard packaging paper, which is usually used for packaging products such as high-end gift boxes and book covers. It has good compression resistance and durability, and can protect the packaged items from external damage.

Food packaging paper is usually made of non-toxic and harmless materials to ensure its safety. This type of packaging base paper is mostly lightweight paper, suitable for packaging food, candy, tea and other products.

The application of packaging base paper is very wide, covering almost all areas of commodity packaging. The following are several main application scenarios:

The application of packaging base paper in food packaging is very important. It can not only effectively prevent moisture and oxidation, but also ensure the hygiene and safety of food. For example, cake boxes, beverage boxes, snack packaging bags, etc., often use packaging base paper as the main material.

The packaging of electronic products is crucial to protecting products. The role of packaging base paper in this type of packaging is mainly reflected in its impact resistance and pressure resistance. It is often used in the outer packaging boxes of electronic products and the protective packaging lining.

In the cosmetics industry, packaging not only needs to meet the protective requirements, but also needs to have a certain aesthetics. Through surface coating and printing, packaging base paper can provide high-quality appearance and protection functions for cosmetic packaging.

The application of packaging base paper in gift and high-end commodity packaging often needs to focus on its visual effects and high-end feel. For example, gray board is often used to make high-end gift boxes to show the value of the brand and the quality of the product.

In the transportation and logistics industry, packaging base paper is often used to make cartons, corrugated cardboard and other materials for packaging goods and ensuring the safety of goods during transportation. Corrugated cardboard is widely used in transportation packaging due to its compression resistance and cushioning properties.

With the continuous changes in environmental protection requirements and consumer demand, the production and application of packaging base paper are also evolving. The main development trends of packaging base paper in the future include:

With the improvement of global environmental awareness, the sustainability of packaging base paper has become an important research and development direction. Many companies have begun to use recyclable and degradable raw materials to reduce the burden on the environment.

In the future, packaging base paper will pay more attention to functionality, not only meeting basic packaging needs, but also realizing intelligent functions, such as anti-counterfeiting, moisture-proof, antibacterial, etc., to enhance the added value of packaging.

The design of packaging base paper will become more diversified, not only focusing on the aesthetics of the appearance, but also taking into account the protection function and convenience of the product. The innovation of packaging base paper will provide enterprises with more design space and marketing advantages.