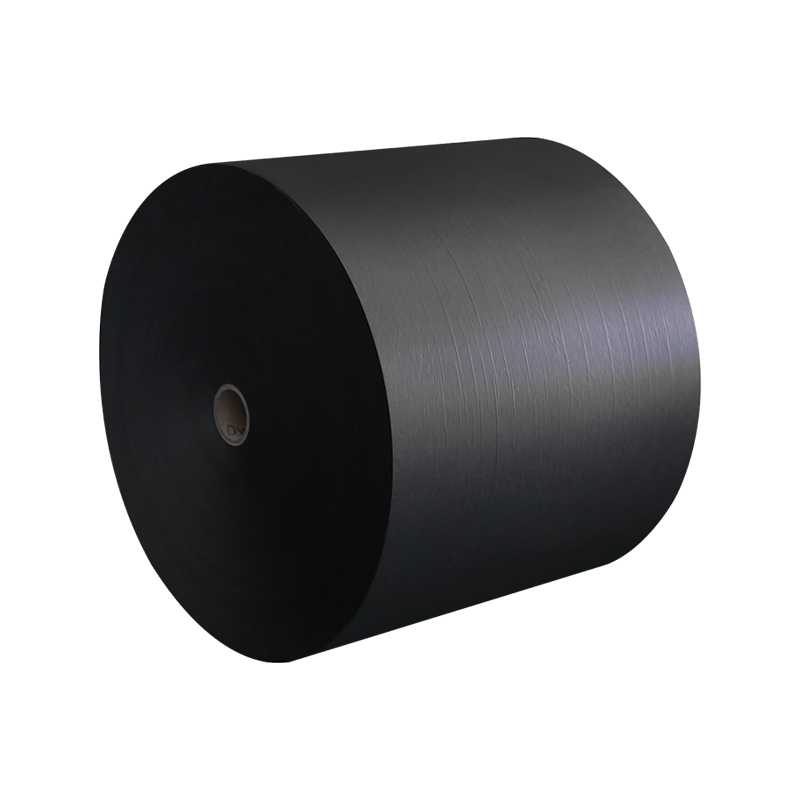

Woven base paper as a special industrial paper, plays an important role in many fields due to its unique structure and properties. From filter materials to reinforcement materials, woven base paper has become an indispensable part of industrial production with its excellent durability and adaptability. This article will introduce the characteristics, application fields, production process and market prospects of woven base paper in detail.

Woven base paper has high tensile strength and pressure resistance through a special weaving process.

The weaving structure makes the base paper have good air permeability and is suitable for applications that require air or liquid to pass through.

Woven base paper usually has good chemical corrosion resistance and can resist the erosion of a variety of chemicals. The density, thickness and material of woven base paper can be adjusted according to different application requirements.

Application fields of woven base paper

In industries such as chemical and pharmaceutical, woven base paper is often used as a filter medium for separating solid particles and liquids. In construction and civil engineering, woven base paper can be used as a reinforcement material to improve the stability of the structure. In electrical engineering, woven base paper is used as an insulating layer for cables and motors due to its good insulation properties. Due to its strength and durability, woven base paper is also commonly used for packaging heavy items.

Production process of woven base paper

According to the application requirements of the final product, select the appropriate paper or fiber material.

Through a special weaving machine, the fibers are woven into base paper according to a predetermined pattern.

The woven base paper is heat treated to enhance its structural stability and durability.

As needed, the woven base paper is coated, impregnated or otherwise post-treated to meet specific performance requirements.

Key points for selecting woven base paper

According to the specific needs of the application scenario, select woven base paper with corresponding strength, air permeability or other characteristics.

Consider whether the raw materials of the woven base paper are environmentally friendly and meet the requirements of sustainable development.

On the premise of meeting performance requirements, choose cost-effective woven base paper.

Choose a supplier with a good market reputation and quality assurance.

Market prospects of woven base paper

With the continuous advancement of industrial technology and the improvement of environmental awareness, woven base paper, as a multifunctional and environmentally friendly industrial material, will continue to grow in market demand. Especially in the fields of new energy, environmental protection engineering and high-end manufacturing, woven base paper has broad application prospects.

Woven base paper plays an important role in many industrial fields with its unique physical and chemical properties. With the continuous innovation of technology and the development of the market, the application scope of woven base paper will be further expanded, bringing more possibilities for industrial production. Choosing high-quality woven base paper can not only improve the performance of the product, but also be responsible for the environment.