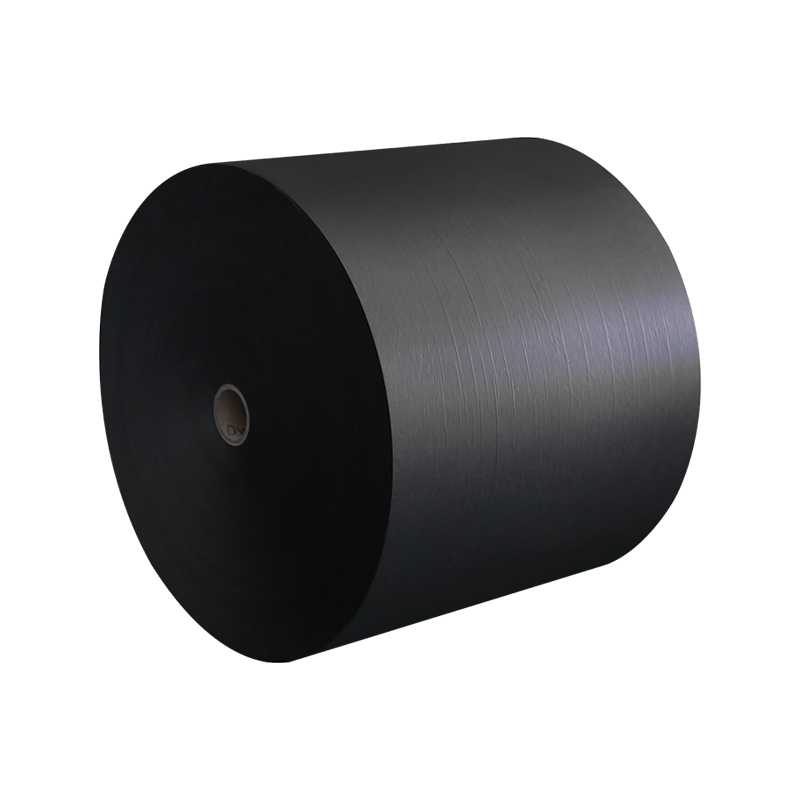

Woven base paper is an innovative and versatile material that is widely used in various industries, combining the qualities of traditional paper with the strength and durability of woven fibers. This unique material is known for its excellent tear resistance, high strength, and diverse applications, ranging from packaging and laminates to decorative surfaces.

Woven base paper is a composite material that consists of woven fibers, typically made from materials like polyester or cotton, combined with a paper base. This fusion of woven fabric and paper creates a highly durable and flexible material that offers the best properties of both components. The woven structure enhances the paper’s tear resistance and tensile strength, making it suitable for demanding applications where conventional paper would fail.

The manufacturing process of woven base paper involves embedding woven fibers into a paper matrix, resulting in a material that is both strong and lightweight. Depending on the end-use, woven base paper can be treated with coatings or resins to enhance its specific characteristics, such as water resistance, flexibility, or surface smoothness.

One of the primary benefits of woven base paper is its exceptional strength and durability. The woven fibers provide structural reinforcement, allowing the material to withstand heavy loads, sharp impacts, and harsh environmental conditions. This makes woven base paper an ideal choice for applications requiring high durability, such as packaging, floor laminates, and industrial wrapping materials.

Traditional paper is prone to tearing and puncturing under stress. However, woven base paper’s reinforced structure ensures it can resist tearing, even under extreme conditions. This property makes it particularly useful in applications such as packaging for heavy or sharp objects, where high tear resistance is critical.

Despite its strength, woven base paper remains lightweight and flexible. This combination of strength and lightness allows for easy handling and transportation, making it suitable for industries that require efficient and economical packaging materials. The flexibility of woven base paper also allows it to conform to various shapes and surfaces without compromising its structural integrity.

Woven base paper can be easily customized to meet specific requirements. It can be coated, printed, or laminated with different materials to achieve desired finishes, including glossy, matte, or textured surfaces. This makes woven base paper a popular choice for decorative applications such as wall coverings, furniture laminates, and flooring, where both aesthetics and durability are important.

Many woven base papers are produced using recyclable and biodegradable fibers, making them an environmentally friendly option compared to traditional plastic-based materials. Additionally, the durability and longevity of woven base paper reduce the need for frequent replacements, further minimizing waste.

One of the most common applications of woven base paper is in the packaging industry. Its strength, tear resistance, and lightweight properties make it ideal for packaging heavy or delicate items. Woven base paper is often used for protective wrapping, industrial packaging, and as a base material for multi-layer packaging solutions. Its ability to withstand rough handling ensures that goods remain safe during transport and storage.

Woven base paper is widely used in the production of decorative laminates for furniture, walls, and flooring. Its customizable surface allows it to mimic various textures and patterns, providing an aesthetically pleasing finish. The durability of woven base paper also ensures that these decorative surfaces are resistant to wear, scratches, and moisture, making them ideal for high-traffic areas such as offices, homes, and commercial spaces.

In industrial settings, woven base paper is used for a variety of purposes, including reinforcement in composites, insulation materials, and as a backing for adhesives. Its strength and heat resistance make it suitable for use in demanding environments, such as in the automotive and construction industries.

Woven base paper’s durability and customizable surface make it an excellent choice for printing and labeling applications. It can be used for high-quality, long-lasting labels on products, ensuring that they remain legible and intact throughout their lifespan. Additionally, woven base paper’s ability to resist moisture and tearing makes it suitable for labels that need to withstand harsh conditions, such as those found in outdoor or industrial environments.

Woven base paper is a highly versatile material that offers a wide range of benefits, from its superior strength and tear resistance to its lightweight and customizable surface. Its ability to withstand tough conditions while maintaining flexibility and durability makes it an essential material in various industries, including packaging, laminates, and industrial applications.