In modern packaging and industrial manufacturing, woven base paper, as a new type of paper material, is gradually replacing traditional paper and textiles and becoming an ideal choice for many industries. With its unique structure, durability and environmental advantages, it is widely used in packaging, construction, home furnishing and other fields.

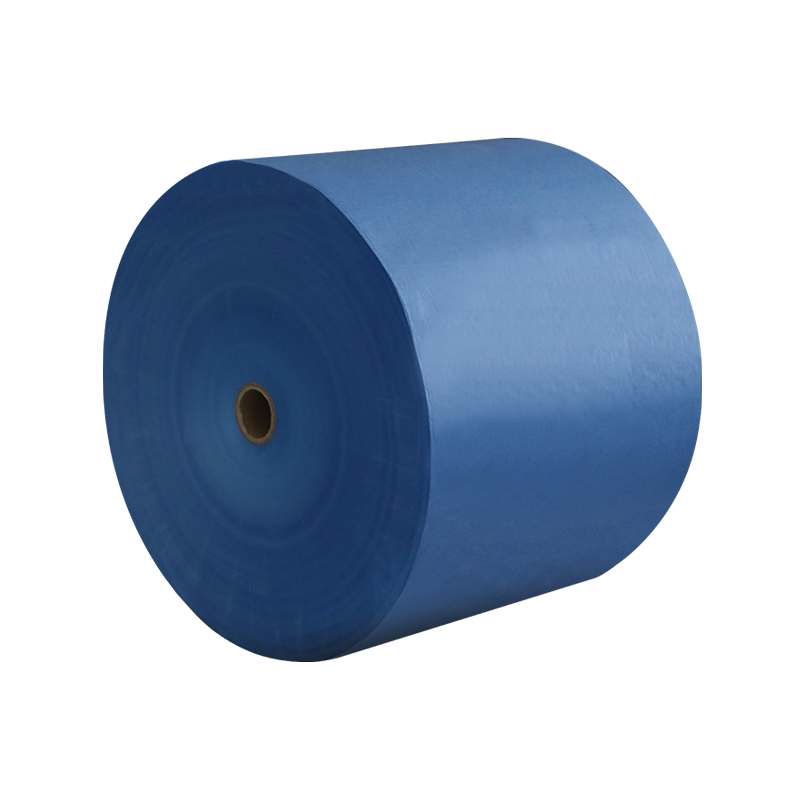

Woven base paper is a kind of paper made from pulp and other natural fibers (such as cotton, linen, synthetic fibers, etc.) after special processing. The surface of this paper has a texture similar to woven cloth, which is usually stronger and more durable than traditional paper, and has higher tear resistance and moisture resistance. It not only has the lightness of paper, but also has high strength and flexibility like fabric. These characteristics of woven base paper make it widely used in packaging, industry and home furnishing.

The production process of woven base paper usually includes the following steps:

The production of woven base paper starts with material selection, usually using natural fibers (such as wood pulp, cotton fiber, linen fiber) or synthetic fibers. After proper treatment, these fibers are mixed with pulp to form a base paper with high plasticity.

The pulp is evenly spread and formed into paper through mechanical processes. During this process, the fibers of the paper are interwoven to form a woven structure. This structure gives the paper stronger tensile and tear resistance.

The surface of the woven base paper is usually treated with special treatments, such as coating, calendering or coating, to enhance the paper's wear resistance, water resistance and visual effects. These treatments make the woven base paper more durable and beautiful.

The treated woven base paper is further processed through a drying device to ensure that the paper is completely dry and give it the required strength and elasticity. Finally, the paper is cut into different sizes and is ready to enter the market.

Woven base paper is widely used in many industries due to its excellent physical properties:

One of the most widely used applications of woven base paper is as a packaging material. Its high strength and tear resistance make it perform well in the packaging industry, especially in packaging that needs to withstand heavy pressure or large loads. For example, woven base paper is often used as a lining material for food packaging bags and bagged products (such as coffee beans, rice, and sugar). Compared with traditional paper bags or plastic bags, woven base paper is more degradable and more in line with environmental protection needs.

In the construction industry, woven base paper is often used as ground protection film, wall protection material, etc. Its wear resistance, tear resistance and waterproof properties make it have important application value in construction. Especially in ground and wall construction, woven base paper can effectively prevent the penetration of dust and pollutants and protect the completed construction surface.

Woven base paper is also widely used in the home and decoration industry because of its beautiful and durable characteristics. For example, it can be used as a base for wall decoration materials or as a protective layer for furniture. Due to its unique texture and color, woven base paper also plays a decorative role in some furniture and household items.

Woven base paper is also widely used in the industrial field, especially in the manufacture of high-strength industrial products. For example, in the textile, building materials, automobile and other industries, woven base paper is often used as a cushioning material or reinforcement material. Its high temperature resistance and corrosion resistance make it play an important role in the packaging and protection of industrial products.

With the increasingly stringent environmental protection regulations, the advantages of woven base paper as an environmentally friendly material are becoming more and more obvious. Woven base paper is usually made of natural fibers or recyclable synthetic fibers. Less chemical additives are used in its production process, and it can be completely recycled. This makes woven base paper have great market potential in modern green and environmentally friendly packaging and building materials.

Compared with plastics and some composite materials, woven base paper can not only be recycled after use, but also has a shorter degradation cycle, reducing the environmental burden. In addition, since its raw materials are mostly natural plant fibers, the production process of woven base paper has relatively little pollution to the environment, which meets the needs of sustainable development.

With the improvement of environmental awareness and the continuous innovation of technology, the application prospects of woven base paper are very broad. In the future, woven base paper may find applications in more fields, such as electronic product packaging, pharmaceutical packaging, etc. At the same time, with the continuous improvement of production technology, the performance of woven base paper will continue to improve and become the preferred material for more industries.

With the advancement of green environmental protection policies, consumers and enterprises will further increase their demand for sustainable packaging. As an environmentally friendly and durable material, woven base paper will be more widely used worldwide.

With its unique structure, durability, environmental protection and other advantages, woven base paper has become an important material in many industries. Whether in packaging, construction, home or industry, the application of woven base paper demonstrates its unparalleled versatility and reliability. With the development of technology and the growth of environmental protection needs, woven base paper will play a more important role in future development and contribute to sustainable development and green economy.